Project Overview

Contract farming bridges the gap between farmers and buyers through pre-agreed contracts. For farmers, it answers the question of where to sell and at what price, while buyers gain consistent supply, quality, and traceability.

Under these agreements, farmers commit to produce specific crops or livestock, and buyers commit to purchase them at agreed standards, timelines, and prices. Inputs like seeds, fertilizers, and training are often provided by buyers.

This model is widely used in crops like tobacco, cotton, sugarcane, as well as poultry, dairy, fruits, and vegetables. Governments in countries such as India, Kenya, Zambia, and Vietnam support contract farming to modernize agriculture and secure farmer incomes.

About client

About client

Park Industries Limited is a Zambia-based tobacco manufacturer that partners directly with farmers through contract farming. It supplies inputs seeds, fertilizers, and technical support to ensure quality yields, and in return farmers deliver crops under agreed terms. This model secures reliable raw material for production, strengthens market access for farmers, and positions Park Industries as a leader in Zambia’s tobacco sector and a partner in rural development.

Challenges We Faced

Scattered Farmer Records

- Managing hundreds of contract farmers with manual spreadsheets or paper ledgers.

- Difficulty reconciling inputs supplied versus crops delivered.

Manual Accounting & Settlements

- Time-consuming reconciliations between what the company owes farmers and what farmers owe for inputs.

- High risk of errors, delays, and disputes.

Reporting & Decision-Making Gaps

- Financial and operational reports took days or weeks to prepare.

- Management lacked real-time data on costs, farmer performance, or inventory levels.

Weak Quality Control Tracking

- Quality checks at each stage often documented on paper, making follow-up and traceability difficult.

- Risk of non-compliance with industry regulations.

Lack of Production Visibility

- Tobacco processing has many stages; without a system, it was hard to track progress, WIP, and yields.

- No clear visibility into by-products, waste, or grade outputs.

Inefficient Inventory Control

- Inputs distributed to farmers, raw tobacco received, and finished goods stored across multiple warehouses were difficult to manage manually.

- Stock mismatches between records and reality.

Scalability Issues

- As the business grew, manual and Excel-based systems could not keep up.

- The need for a centralized, integrated system became unavoidable.

Solution Implemented

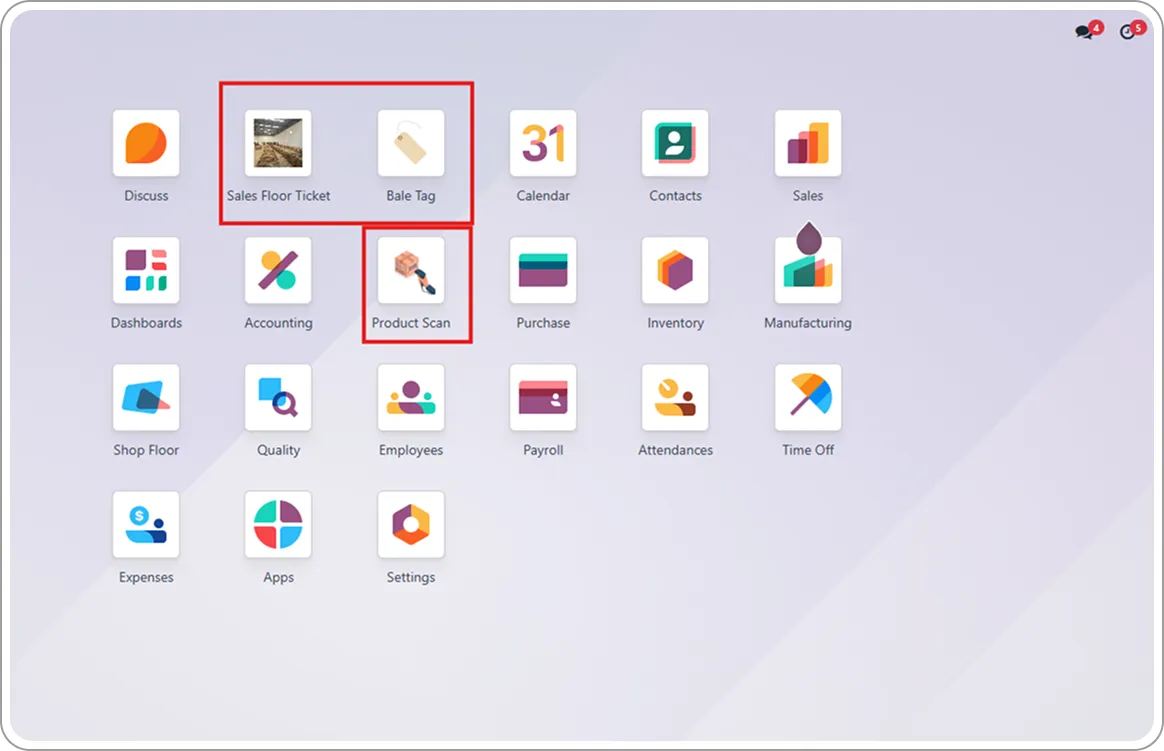

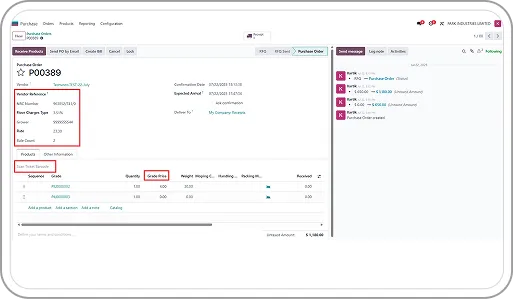

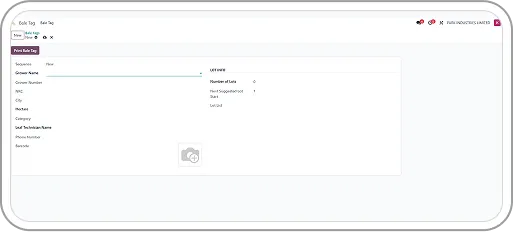

- Designed a custom Bale Ticket module with unique sequences for effective tracking of farmer deliveries.

- Each bale is assigned a barcode-enabled ticket containing detailed crop and farmer information.

- When scanning a Bale Ticket, the system automatically retrieves all relevant information.

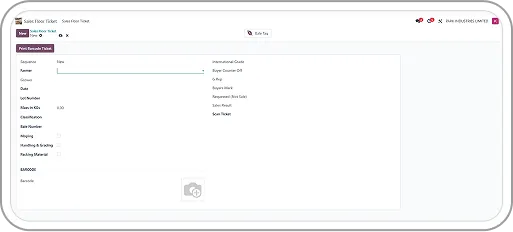

- A Sales Floor Ticket is generated with tobacco grades clearly printed, ensuring transparent classification.

- Upon scanning the Sales Floor Ticket, products are instantly created and added to the purchase order line.

- This streamlined the entire farmer-to-purchase cycle, reducing manual data entry and errors.

- Delivered customized operational & financial reports for farmer settlements, inventory tracking, manufacturing efficiency, and HR compliance.

- Enabled management to access real-time insights and make informed decisions.

Bale Ticket Management

Sales Floor Ticket Automation

Purchase Flow Integration

Comprehensive Reporting Suite

To address the client’s operational and compliance challenges, we deployed a fully customized Odoo ERP tailored to the tobacco manufacturing and contract farming model of Park Industries Limited.

- Implemented an automated lot number generation process to enable precise stock tracking across warehouses and manufacturing stages.

- Ensured full traceability from farmer delivery to finished goods.

- Fully integrated the multi-stage tobacco manufacturing workflow into Odoo.

- Introduced product returns by percentage, capturing by-products, wastage, and yield accurately.

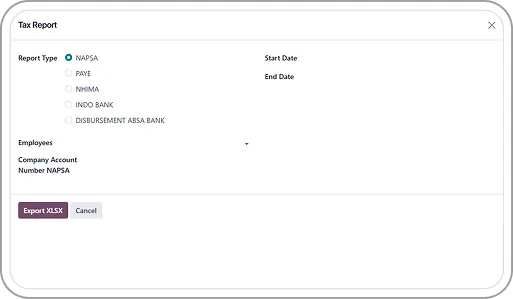

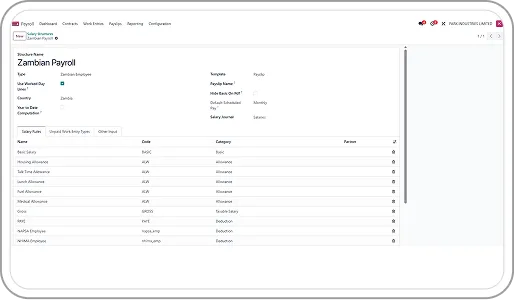

- Developed a Zambia-specific payroll system within Odoo.

- Configured salary rules, deductions, and contributions compliant with local regulations.

- Built multiple custom HRMS reports to streamline compliance and employee management.

- Key statutory reports include:

Unique Lot Numbering System

Manufacturing with Returns

Custom Payroll for Zambia

Regulatory & HRMS Reports

Technologies We Leveraged

- ERP: Odoo

- Backend: Python

- Framework: Owl JS, JSON RPC

- Database: PostgreSQL

- DevOps & Deployment: Docker + CI/CD pipeline

Benefits

Accurate, Error-Free Data Capture

Manual entry often caused delays and mistakes. By introducing barcode scanning, bale and ticket data flow seamlessly into the system, saving time and ensuring accuracy.

Real-Time Insights for Decision Making

Earlier, management relied on outdated data to make decisions. With custom dashboards and reports, they now have real-time visibility across finance, HR, inventory, and manufacturing.

End-to-End Stock Traceability

Tracking grades and stock movement was difficult before. With unique lot numbers, every bale and finished product is traceable across warehouses and manufacturing stages.

Compliance-Ready Payroll

Payroll processing was prone to errors under manual methods. The custom Zambian payroll module ensures correct deductions (NAPSA, NHIMA, PAYE) and fully compliant employee settlements.

Automated HR & Statutory Reporting

Preparing compliance reports like NAPSA or NHIMA used to take hours or days. Now, these reports are generated instantly and error-free within Odoo.

Scalability for Future Growth

As the business expanded, manual processes became a bottleneck. With a single integrated ERP, Park Industries can scale operations without adding complexity.

Farmer Transactions Made Transparent

Previously, farmer deliveries and settlements were scattered across ledgers and spreadsheets, leading to disputes. Now, with the automated Bale → Sales Floor → Purchase flow, every step is digitized and transparent.

Streamlined Manufacturing Control

Managing multiple production stages and returns was complex on paper. The new integrated manufacturing workflow captures yields, by-products, and wastage automatically, improving efficiency and cost accuracy.

Transform Your Tobacco Farming Business with AI-Driven Odoo ERP

Contract farming is complex but managing it doesn’t have to be. With Odoo ERP, you can digitize farmer contracts, streamline input supplies, track crops in real time, and automate payments all while staying compliant.

Talk to Our Experts TodayDrive Transparency, Control,

& Trust with Odoo ERP

Drive Transparency, Control,

& Trust

with Odoo ERP

Real-Time Dashboards for Decision-Makers

Odoo ERP provides customizable dashboards that give managers a 360° view of contracts, input supplies, procurement status, and farmer settlements. This ensures data-driven decisions instead of guesswork.

Global Trade & Compliance Advantage

International buyers demand transparency. Odoo ERP ensures traceability of every leaf from farm to warehouse, helping tobacco companies build trust with regulators and export markets.

Farmer Empowerment

By ensuring fair input allocation, faster payments, and transparent contracts, companies strengthen farmer relationships, leading to loyalty and long-term partnerships.

// We are here to help you

Trusting in Our Expertise

- 30 Hours Risk Free Trial.

- Direct Communication With Developer.

- On-time Project Delivery Assurity.

- Assign Dedicated PM.

- Get Daily Update & Weekly Live Demo.

- Dedicated team 100% focused on your product.

- Sign NDA for Security & Confidentiality.